implementation

- Rebates & Incentives

- Feasibility Study

- Energy Benchmarking

- Project Construction Management

- Energy Procurement

- learn more about our services

Details

- Square Footage: 60,000

- Year Built: 2000

- Location: Mount Vernon, NY

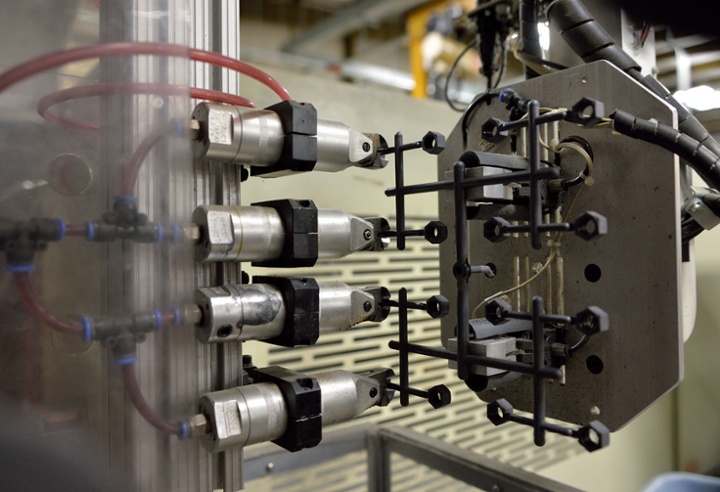

ISO Plastics, a manufacturer of injection-molded plastic components, hired EN-POWER GROUP to develop and implement a comprehensive energy and engineering plan for their 60,000 sqft industrial facility in Mount Vernon, New York. This wide-ranging study incorporated energy benchmarking, energy auditing, and utility and tariff analysis to create an energy master plan for the facility.

To help ISO Plastics identify the most cost-effective energy conservation measures for its manufacturing facility, EN-POWER GROUP’s first step was to understand how the property used its energy. We began by enrolling the property in NYSERDA’s FlexTech Benchmarking program, which provided a rebate for energy benchmarking and auditing. Energy benchmarking compares a building’s current energy usage against its past usage and against buildings of similar size and type. The benchmarking results revealed the facility consumed higher levels of energy than comparable properties, and the on-site energy audit indicated several process equipment upgrades could reduce energy use.

Using the knowledge gained from benchmarking and auditing, our engineers helped ISO Plastics enter into a more favorable energy contract. Next, we worked with ISO Plastics’ management to create an energy master plan focused on selecting cost-effective upgrades that maximized the use of available incentives. As part of this plan, ISO Plastics installed a new 700-ton injection molding machine that decreased peak demand, lowered operating costs, and increased manufacturing productivity. The energy upgrade was partly funded through ConEdison’s Commercial & Industrial (C&I) Program.

Project Achievements

- 156,600 kWh

Annual Utility Savings - $32,000

Annual Utility Cost Savings - 44 kW

Demand Saved - $25,000

Total Eligible Rebates - $143,000/strong>

Total Project Cost After Rebates - 4.5 years

Simple Payback

Project Highlights

Created and implemented an energy master plan that included replacement of process equipment and energy cost reduction.

Related Projects

Custom Solutions For Your Building's Complex Energy Needs

To support New York City’s ambitious goal of achieving carbon neutrality by 2025, Municipal Courts have enacted local laws that impose significant financial.